Snowmaking System Engineering

SMS Engineering ProcessDelta SMS advantages

1. Site survey

2. Data collection for design

1. Preliminary Design Phase:

- 1) Site Survey: required facilities location & soil status

- 2) MCB location, Sizing, Layout

- 3) Pipeline Mountain Distribution & Specification(Air & Water)

- 4) Drainage Vault location

- 5) Underground Tank Location & Sizing

- 6) Weather Station Location

- 7) Major Equipment Specification:

- Air Compressor

- Water Pump

- Fluid Cooler

- Motor Control Center

- Control Valve

- 8) Air/Water Hydrant Location

- 9) System schematic Flow Diagram

- 10) Control System schematic Design

- 11) Power One-Line Diagram

- 12) Power Receptacle Location for Fan Gun

- 13) Motor List

- 14) Air & Vacuum Vent Location

- 15) Valve Schedule

- 16) Application Standards

2. Project Schedule

3. Procurement Schedule for the Equipment

4. Construction Schedule

Detail design Drawing list

- 1) Process & Instrumentation Diagram

- 2) Air/Water Pipeline Mountain Distribution

- 3) Air/Water Piping Details

- 4) Air/Water Hydrants Mountain Layout

- 5) Air/Water Hydrants Assembly Details

- 6) MCB Control Room Details

- 7) MCB Control Room Details

- 8) MCB & PPH General Layout, Elevations, Foundations

- 9) MCB & PPH Foundation Section & Details

- 10) Garage Building Layout & Foundation Details

- 11) MCB Air System Isometric Drawings

- 12) MCB Cooling System Isometric

- 13) PPH Water System Isometric

- 14) PPH water System Layout

- 15) PPH water System Sections & Details

- 16) MCB Air Intake System

- 17) MCB Air System Layout

- 18) MCB Air System Sections & Details

- 19) MCB Cooling System Layout

- 20) MCB Cooling System Sections

- 21) MCB Instrument Air Plan

- 22) MCB Instrument Air Section & Details

- 23) Instrumentation & Control Plan

- 24) Instrument & Control Devices Arrangement

- 25) Power System One Line Diagram

- 26) Electrical power Distribution Plan

- 27) MCB & PPH lighting Plan

- 28) Control & Instrumentation Typical Details

- 29) Fan-gun Power Outlet Station

- 30) Fan-gun Power Mountain Distribution

- 31) Pump & Compressor Starter Diagram of Principle

- 32) Control System Plan

- 33) Instrument Air Compressor Diagram of Principle

- 34) Solenoid Valve Control termination Diagram

- 35) Drain Valve Vault Controller Layout & Wiring Diagram

- 36) Control System Terminal Enclosure Layout & Wiring Diagram

- 37) Pump & Compressor Motor RTD's Termination Wiring Diagram

- 38) Motor Space Heater Control Termination Diagram

- 39) Control Valve Pneumatic Schematic Diagram

- 40) AC & DC Power Supply & Communications Diagram

- 41) Communications System Termination Diagram

- 42) Weather Station Layout & Details

- 43) Others if necessary

Delta Snowmaking System Special Advantages

Delta Snowmaking Systems have a distinct advantage over other snowmaking systems because of Delta’s integrated high technology concepts that produce more snow on a “System Wide Basis” more efficiently and at a lower cost.

- Delta design and engineering-specialized techniques and over 30 years of proven results.

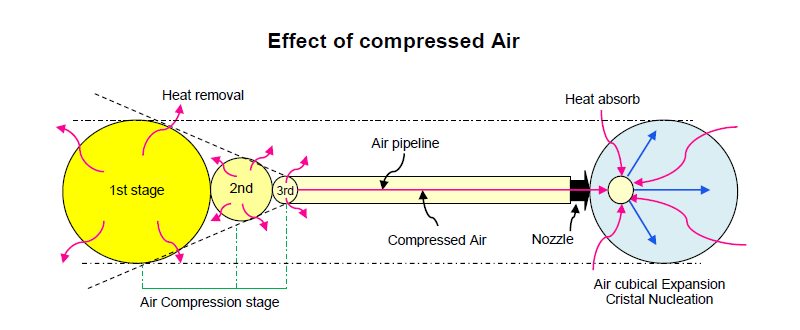

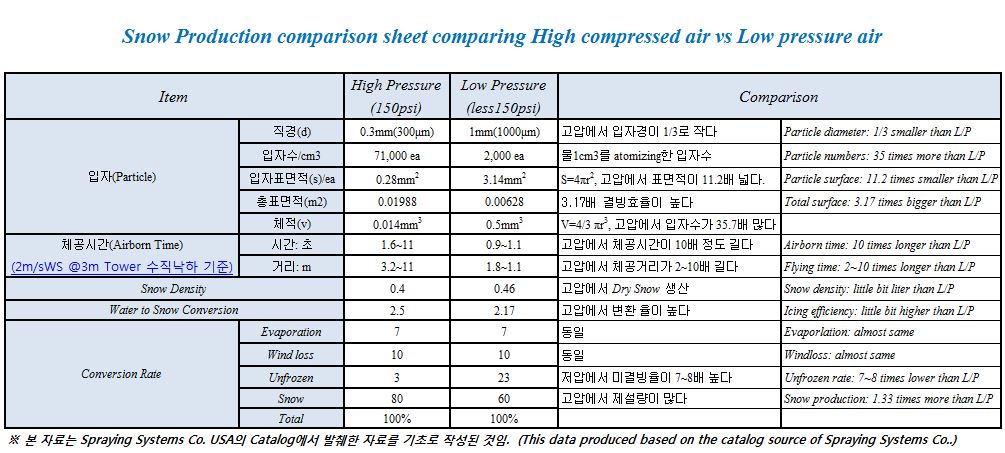

- Higher Air Pressure of 10.3bar(150psi) that results in more efficient snowmaking because of the effective available energy delivered at the gun to remove heat from the water. The terminal velocity of the water droplet is lower because of the smaller droplet size therefore providing a longer flight time for total freeze out of the water particle. Higher air pressure is also more effective at marginal temperatures. On a system performance basis the higher air pressure will perform approximately 40% better than systems running at 7bars air pressure.

- The Delta Control System Software for full & semi automatic interactive control can increase the snowmaking performance by as much as 50% over manually run systems.

● Advantages of Snoforce™ FULL-AUTOMATIC SYSTEM- General

- Fastest on-line and off-line method of control for starting-up and shutting-down of the snowmaking system. This features advantage is equivalent to approximately an additional 2.7% increase in snowmaking production over a semi-automatic system.

- The automatic system adjustments to the nozzles then temperature changes occur are performed more quickly. This enables the system to have almost full utilization of the snowmaking window of operation. An additional 2% increase in the snowmaking production is achieved by using this method of control over the semi automatic system.

- The automatic system can be programmed to make snow in certain area by priority each day. The automatic system, in theory, can be started up and operational without operators or snowmaking crews. This includes the plant machinery and snow-guns on the fill.

- Technology

- As per A-a) above, the calculation is as follows; (for example) total snowmaking hours 494 over a 40 day period. Even if the snowmaking system shut-down every day and restarted every day, the maximum would be 40 starts @ 30 nozzles @ 20 seconds each = 6.6 hours.

The semi automatic start for 30 nozzles is approximately 30 minutes x 40 starts = 20 hours. The differential is 13.6 hours at 13.6/494 = 2.7% - As per A-c) above, the estimate is as follows; the response time of full automatic or Delta semi-automatic is negligible because Delta AUTOTRAK dose the same thing as full automatic to follow temperature changes. Resetting and adjustment is estimated at 10 hours or 10/494 = 2%

- Depending upon labor law, the system could theoretically operate without personnel.

- As per A-a) above, the calculation is as follows; (for example) total snowmaking hours 494 over a 40 day period. Even if the snowmaking system shut-down every day and restarted every day, the maximum would be 40 starts @ 30 nozzles @ 20 seconds each = 6.6 hours.

- Economics

- The combination of B-a and B-b above would increase snowmaking production by approximately 4.7%.

- General

- The Delta nozzle. The Delta nozzle on a system wide basis can increase the system performance by as much as 40% to 80% over other snowmaking nozzles. This highly efficient air/water ratio nozzle is the end producer of snow that uses lower air consumption per volume of water consumption than other snowmaking nozzles.

- FUEL TANK

No fuel tank was specified because no engine driven compressors were recommended. - WATER COOLING

No water cooling tower was specified because Delta does not recommend water cooling towers as an economical investment for the rate of increase in snowmaking production until the water temperature exceeds 12℃. - BOOSTER PUMP HOUSE

Delta snowmaking system design for the client does not require the use of any booster pump houses therefore none are specified. - VALVE BLOCK HOUSE-M.O.V.FIELD LINE ISOLATION

Delta snowmaking design for the client does not require or recommend the use of Valve Block Houses and Motor Operated Line Isolation Valves. The pipeline is a circulatory design buried to 1.5m that does not require the use of that equipment.